Riderless Flat Steel Healds are integral components of weaving looms, responsible for lifting and lowering warp threads to create the desired fabric pattern. They are renowned for their durability, strength, and resistance to corrosion, making them a popular choice for textile manufacturers around the world.

If you are seeking high-quality Riderless Flat Steel Healds Manufacturer and Supplier, look no further than Eagle Drop Wires. We are a leading manufacturer and supplier of these essential weaving components, committed to providing our customers with Unmatched Quality, Competitive Prices, Extensive Inventory, Prompt Delivery and Dedicated Support.

High carbon hardened and tempered bright polished spring steel strips with rounded edges are used to make halberds. Stainless steel Healds are another option.

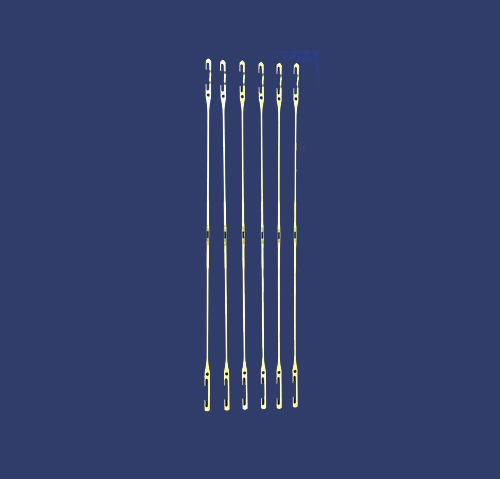

End loops : The `O’ type for Rider-type Heald frames. ‘C’ / ‘J’ type End Loops for Rider-Less Heald Frame can be offered with hole below the loop for facilitating storage of Healds for easy insertion of Healds in the Heald Frames and also for the Automatic Drawing-In.

To distinguish the Healds: a differentiated shape for the End loop is provided based on thickness measurements of 0.25mm, 0.3mm, and 0.38mm.

Heald Eyelet: A variety of Heald Eye shapes and sizes can be provided, with options for 5mm and 10mm off-center placement. To provide a smooth surface, extra care is taken during the polishing, deburring, and edge rounding processes at Heald Eye.

Protection against rust: Our Riderless Healds come with appropriately bright zinc plating OR Nichrome.

Why Choose Riderless Flat Steel Healds?

Several factors contribute to the widespread use of Riderless Flat Steel Healds:

- High Tensile Strength:They can withstand the tension and strain of weaving heavy fabrics without breaking or bending.

- Durable and Long-lasting:Their robust construction ensures long service life, minimizing downtime and maintenance costs.

- Corrosion Resistant:They are often coated with a protective layer to resist rust and corrosion, especially in humid environments.

- Dimensional Stability:They maintain their shape and size over time, ensuring consistent weaving quality.

- Lightweight: Their lightweight design reduces the overall weight of the weaving machine, leading to energy savings.

- Versatile:They are available in various sizes and thicknesses to cater to different weaving needs.

Specification

| Thickness | 0.3mm, 0.4mm, 0.5mm, 0.6mm |

| Size | 280mm, 331mm, 382mm and other as per customer’s specification |

| Thread EYE | 5.5 x 1.2, 6.5 x 1.8, 7.8 x 3.8 |

| Material | Stainless Steel (SS420J2) & High Carbon (H&T) Spring Steel Strips – Nickel Plated. |

| Types of Healds | Simplex, Duplex |

| End Loops Types | C, J, O |

| Brand | “EAGLE DROP WIRES” |