Airjet looms are some of the most advanced and efficient weaving machines on the market. They use jets of air to propel the weft yarn across the loom at high speeds, resulting in a faster weaving process. However, the high speeds of airjet looms place a great deal of stress on the weaving machine’s components, including the drop pins.

What are Airjet Loom Drop Pin?

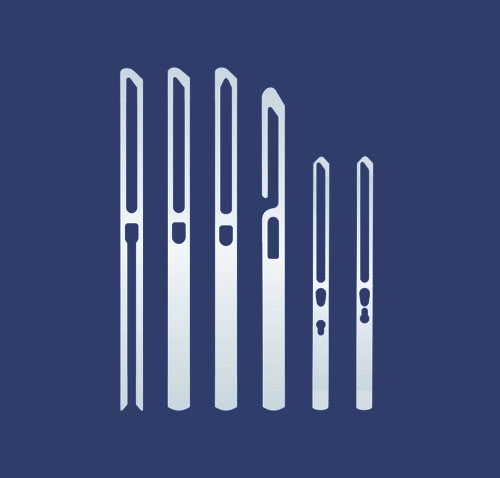

Airjet loom drop pins are small, metal pins that are inserted into the heddles of the loom. They are responsible for lifting and lowering the warp threads to create the shed, which is the opening through which the weft yarn is passed. Drop pins must be strong and durable to withstand the high speeds and forces of airjet weaving.

Why Use Stainless Steel Airjet Loom Drop Pin?

Stainless steel is an excellent material for airjet loom drop pins because it is:

- Strong and durable: Stainless steel can withstand the high speeds and forces of airjet weaving without bending or breaking.

- Corrosion resistant: Stainless steel is resistant to rust and corrosion, which is important in a weaving environment where moisture is often present.

- Smooth: Stainless steel has a smooth surface that helps to prevent snags and breaks in the warp threads.

- Easy to clean: Stainless steel is easy to clean and maintain, which is important for keeping the loom running smoothly.

Benefits of Using Stainless Steel Drop Pins

There are many benefits to using stainless steel drop pins in your airjet loom, including:

- Reduced downtime: Stainless steel drop pins are less likely to break or fail, which can help to reduce downtime and increase production.

- Improved weave quality: Stainless steel drop pins help to create a cleaner and more consistent shed, which can result in a higher quality weave.

- Lower maintenance costs: Stainless steel drop pins are less likely to need to be replaced, which can help to save you money on maintenance costs.

How to Choose the Right Stainless Steel Drop Pins for Your Airjet Loom

When choosing stainless steel drop pins for your airjet loom, it is important to consider the following factors:

- The size of the loom: The size of the drop pins will need to match the size of the heddles on your loom.

- The type of yarn you are using: The thickness of the drop pins will need to be appropriate for the type of yarn you are using.

- The weave pattern you are using: Some weave patterns may require special types of drop pins.

Once you have considered these factors, you can talk to a loom manufacturer or textile supplier to find the right stainless steel drop pins for your needs. In addition to using stainless steel drop pins, there are a few other things you can do to maintain your airjet loom and keep it running smoothly:

- Regularly clean and lubricate the loom.

- Inspect the drop pins for wear and tear and replace them as needed.

- Use the correct tension on the warp threads.

- Avoid weaving with damaged yarn.

By following these tips, you can help to ensure that your airjet loom runs smoothly and efficiently for many years to come.