In the world of textile manufacturing, precision and efficiency are paramount. Every component of a weaving loom plays a crucial role in ensuring the quality and productivity of the final product. One such component that deserves attention is the Mechanical Drop Pin. This blog post explores the significance of Mechanical Drop Pins in weaving loom spare parts, highlighting their role in enhancing efficiency and precision.

Definition and Function

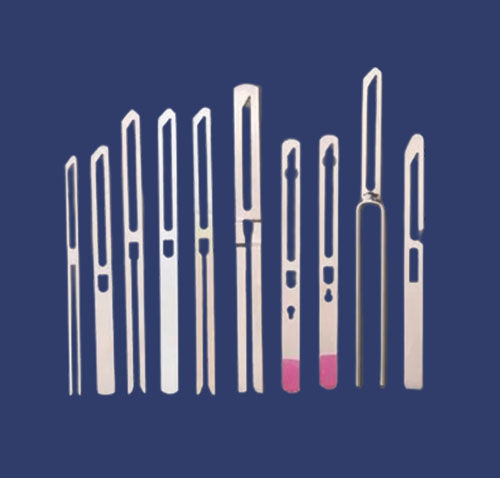

Mechanical Drop Pins are small, yet vital, components used in weaving loom spare parts. These pins are designed to hold the warp threads in place during the weaving process. They ensure the precise alignment and tension of the warp threads, allowing for smooth and accurate fabric production.

Construction and Materials

Mechanical Drop Pins are typically made from high-quality materials such as stainless steel or hardened alloy steel. This ensures their durability and resistance to wear and tear, even under high-speed weaving conditions. The pins are meticulously crafted to have a smooth surface and precise dimensions, enabling seamless movement within the loom.

Advantages of Mechanical Drop Pins

- Enhanced Efficiency

- Improved Warp Thread Control

- Increased Weaving Speed

- Consistent Fabric Quality

- Reduced Defects

Integration of Mechanical Drop Pins in Weaving Loom Spare Parts

Compatibility and Customization: Mechanical Drop Pins are designed to be compatible with various types of weaving looms. They can be customized to fit specific loom models and configurations, ensuring seamless integration into the existing spare parts system.

Easy Installation and Maintenance: Mechanical Drop Pins are user-friendly components that can be easily installed and replaced. Their simple design allows for quick maintenance and reduces downtime during repairs or replacements. This convenience contributes to the overall efficiency of the weaving process.

Mechanical Drop Pins are indispensable components in weaving loom spare parts, playing a vital role in enhancing efficiency and precision. Their ability to control warp thread alignment and tension ensures uninterrupted weaving operations and consistent fabric quality. By reducing defects and increasing weaving speed, these pins contribute to higher productivity and improved profitability in textile manufacturing. With their compatibility and ease of installation, these types of drop pins are a valuable addition to any weaving loom spare parts inventory. Embracing these innovative components can revolutionize the textile industry, enabling manufacturers to achieve new levels of efficiency and precision in their production processes.